1.1 – Building Materials

- Capacity: Production of cementitious products (cement, blended cements, admixtures), low-carbon cement and recycled aggregates, asphalt modifiers, and specialised concrete mixes for roads, housing, and industrial projects.

Strategic Tools & Equipment

- Cement grinding units, batching plants, and admixture dosing systems.

- Asphalt modification plants with polymer and rubber blending capacity.

- QA/QC laboratories accredited to ISO/IEC 17025, equipped with universal testing machines, curing chambers, and durability testing equipment.

Competitive Advantage

- Standards-compliant production aligned with EN, ASTM, and SADC standards.

- Integration with our aggregates and asphalt plants for end-to-end supply chain control.

- Ability to design low-carbon materials (fly ash cement, recycled aggregate concrete) supporting sustainable infrastructure goals.

1.2 – Prefabricated Materials (Culverts & Beams)

- Capacity: Large-scale manufacturing of precast elements such as box culverts, U-drains, bridge beams, kerbstones, and wall panels.

Strategic Tools & Equipment

- Pre-tensioning and post-tensioning jacks for beam production.

- Steel moulds for culverts and U-drains, automated vibration tables, and curing chambers.

- Concrete batching systems with precision dosing and quality monitoring.

Competitive Advantage

- Factory-controlled curing and certification to international standards (EN/ASTM).

- Modular, off-site manufacturing enabling rapid deployment for road, bridge, and water projects.

- Significant cost and time savings compared to traditional on-site construction.

- Proven resilience of prefabricated products in flood-prone and seismically active areas.

1.3 – Supply Chain Coordination

- Capacity: Creation of integrated supply chains for public works, ensuring timely delivery of building materials, prefabricated products, and equipment.

- Strategic Tools & Equipment:

- Vendor-Managed Inventory (VMI): Digital inventory management systems for public and private projects.

- E-Procurement Platforms: Enabling transparent sourcing, bid evaluation, and supplier onboarding.

- Barcode/QR Tracking Systems: For real-time traceability of construction materials and prefabricated elements.

- Competitive Advantage:

- Development of local supply networks with MSME onboarding and technical upskilling.

- Improved accountability, reduced waste, and streamlined project delivery.

- Alignment with regional localisation frameworks to maximise African content in infrastructure projects.

Innovation Edge

- Modular Off-Site Manufacturing: Fast-tracked production of culverts, beams, and panels for rapid bridge/culvert replacement.

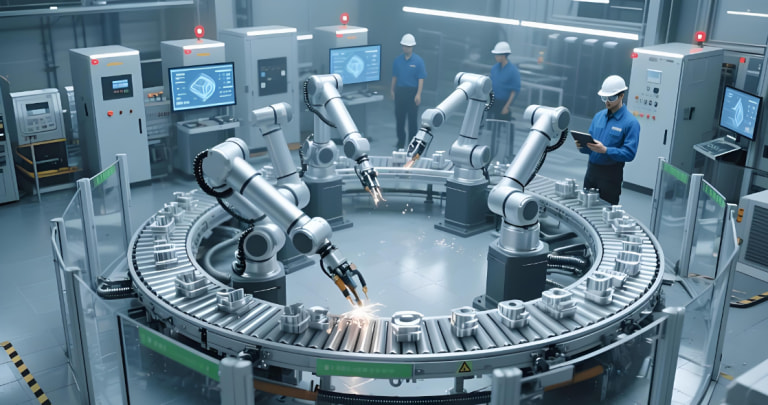

- Digital Production Control (MES): Manufacturing Execution Systems integrated with ERP for precision and efficiency.

- Predictive Maintenance: IoT-enabled sensors for monitoring plant performance, ensuring high uptime and reduced operational costs.

- Sustainability: Circular economy practices through recycling of concrete, steel, and asphalt materials into new production cycles.

1.4 – Agriculture (Agro) Processing Solutions

- Capacity: Production and supply of agro-processing equipment such as milling machines, oil pressing units, grain silos, and irrigation-linked post-harvest technologies.

- Strategic Tools & Equipment: Fabrication workshops, CNC machinery, automated feed processing units.

- Competitive Advantage: Supporting rural industrialisation by integrating agriculture into regional manufacturing value chains.